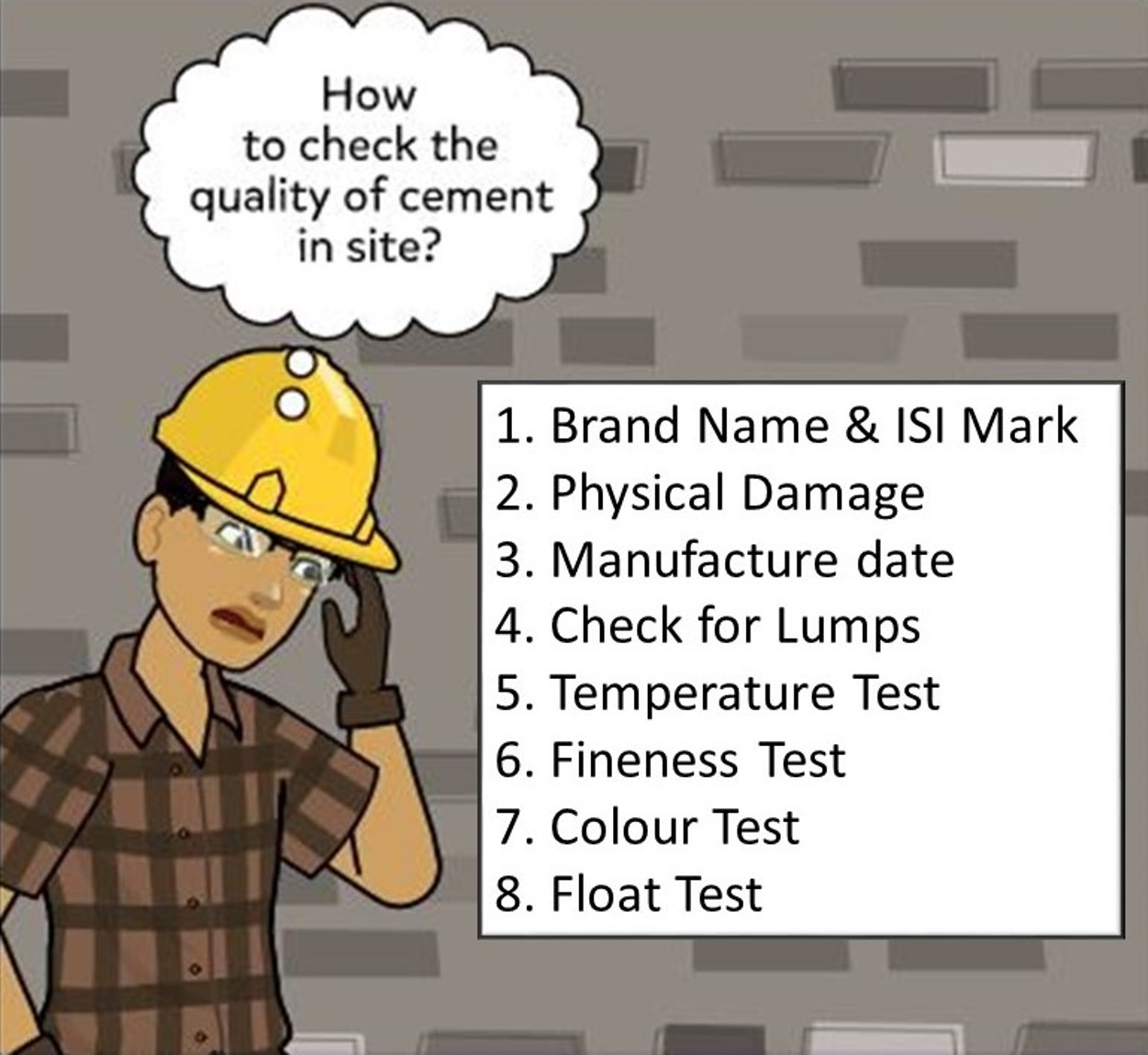

Cement directly affects the strength and quality of concrete. It is therefore essential for civil engineers to be aware of the various methods used to test the quality of cement on a construction site.

This article will show you some simple ways to test the quality of cement in cement bags when supplied by suppliers to the construction area.

Cement is often delivered in 50 kg bags or trucks. Before unloading cement from vehicles, it is advisable to conduct freshness tests and physical property tests.

Check for Brand name, Packaging and Freshness

- Check the brand name and ISI mark.

- Check for physical damage. Punchering and tearing of cement bags can cause cement loss and expose cement to atmospheric moisture. Cement hardens in moist air, so it is important to check for physical damage of cement bags.

- Check for the Manufacturing date. The strength of cement decreases with age due to exposure to moisture and carbonation. It is better to use cement that is less than a month old . Cement that is 3 months old should not be used for any reason.

It is advisable to buy directly from the manufacturer in order to avoid forgery of the manufacturing date and brand name. Remember to do a field test of the quality of the cement in all cases.

Test the Quality of cement through its Physical Properties

- Check for Lumps. If you find hard lumps that do not break easily, it may be a sign of setting of cement due to exposure to moisture.

- Check for temperature. If you insert your finger inside the cement it should feel cool. If cement is very hot it may be because they are loaded directly after it is manufactured without storing. It is better to store and cool the cement before using it.

- Check for Fineness. Rub the cement between your fingers, it should feel smooth. If the cement feels grainy it is a sign that it is adultered with sand or not fully crushed during the manufacturing process.

- Check for Color. Cement should be uniform in color. If the cement is very light greyish in color it may be due to the presence of excessive lime or fly ash.

Laboratory tests to check the quality of cement

- Consistency test. Consistency is a measure of how much water a cement needs. Consistency depends on fineness and type of cement. For PPC and OPC the Consistency value should be around 25 to 35%.

- Compressive strength test. Prepare mortar cubes to check the compressive strength of cement in each batch.

It is a good idea to secure a small amount of cement from each batch in an airtight plastic bag with all the details such as date of manufacture and supplier details. This will be useful in future if any problem arises.

Leave a Reply