Proper batching of cement, fine aggregate(sand) and coarse aggregate(gravel or jalli) is important to obtain good quality concrete. This article will show you how to calculate sand and gravel per 50kg cement bag to produce concrete according to code book.

Let us first understand the role of different materials in the preparation of concrete. Cement strengthens concrete by bonding inert materials, while sand and gravel act as fillers to reduce the use of cement and reduce the shrinkage of concrete.

In terms of strength, concrete is classified into various grades like M5, M7.5, M10, M15, M20 etc. The number in the grade name indicates the strength of the concrete in 28 days.

Weight of Sand and Gravel (Jalli) needed for 1 bag of Cement

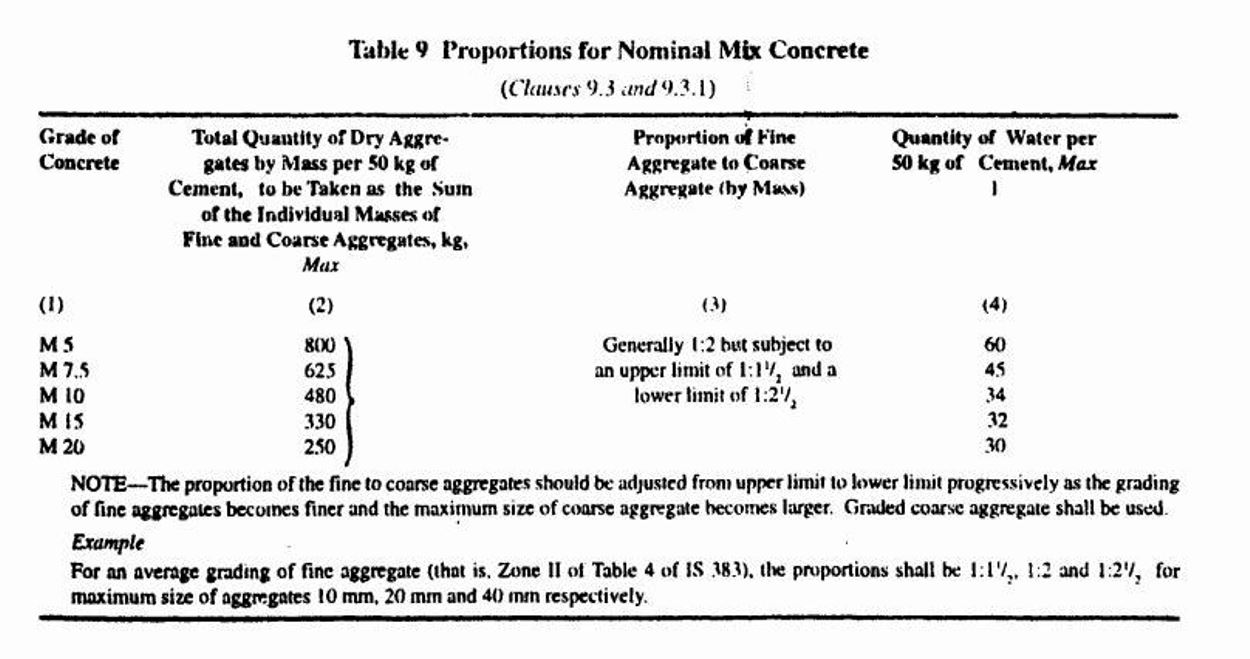

Calculating ingredients by weight is called weigh batching. They are used in places such as ready mix plant and laboratories to get accurate results. The Codebook recommends the following total aggregates (sand + gravel) per 50kg bag of cement. Since sand and gravel are not given separate value, we have to find them ourselves.

| CONCRETE GRADE | CEMENT (BAGS) | TOTAL AGGREGATES (SAND + GRAVEL) |

| M5 | 1 | 800 kg |

| M7.5 | 1 | 625 kg |

| M10 | 1 | 480 kg |

| M15 | 1 | 330 kg |

| M20 | 1 | 250 kg |

The ratio of fine aggregate to coarse aggregate used in concrete is 1:2, i.e. for every 1 part of sand we have to take 2 part of gravel. Hence we have to divide the Total Aggregate into 3 parts and take 1 part as sand and 2 parts as coarse aggregate.

Lets calculate weight of sand and gravel needed for M15 Grade concrete.

Weight of Sand required per bag of cement = (330/3) x 1 = 110 kg

Weight of gravel required per bag of cement = (330/3) x 2 = 220 kg

Therefore to produce M15 Grade concrete, use 110 kg of sand and 220 kg of gravel per bag of cement.

Weight of sand and gravel needed per bag of cement for different concrete grades

| CONCRETE GRADE | CEMENT (BAGS) | SAND (KG) | GRAVEL (KG) |

| M5 | 1 | 265 | 535 |

| M7.5 | 1 | 210 | 415 |

| M10 | 1 | 160 | 320 |

| M15 | 1 | 110 | 220 |

| M20 | 1 | 85 | 165 |

Volume of Sand and Gravel needed for 1 bag of Cement in cubic feet CFT

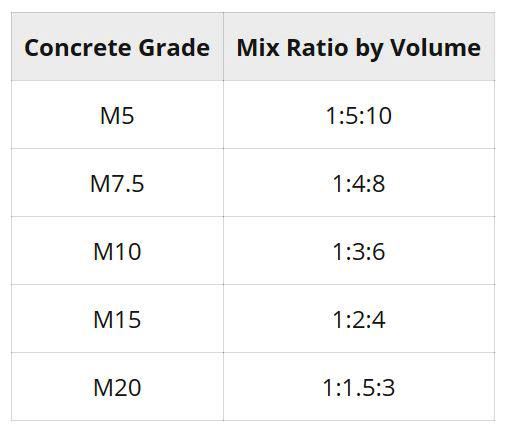

Calculating ingredients by volume is called volume batching. Volume batching is preferred for onsite production of concrete. It is easy and faster than weigh batching. Codebook recommends the following volumetric mix ratios for different grades of concrete.

Lets calculate volume of sand and gravel needed to produce M15 grade concrete

Mix Ratio of M15 grade concrete is 1:2:4. Therefore, for every 1 part of cement, we have to use 2 part of sand and 4 part of gravel to produce M15 ratio concrete. The volume of 50 kg cement bag is 1.25 CFT. The volume of Batching box used in the construction site is also 1.25 CFT.

Mix Ratio of M15 Grade concrete = 1:2:4

Volume of sand needed = Volume of cement bag x Ratio of sand

Volume of sand needed = 1.25 x 2 = 2.5 CFT

Volume of Gravel needed = 1.25 x 4 = 5 CFT

Therefore to produce M15 Grade concrete, 2.5 cubic feet of sand and 5 cubic feet of gravel should be used per cement bag.

Volume of sand and gravel needed per bag of cement for different concrete grades

| CONCRETE GRADE | CEMENT (BAGS) | SAND (CFT) | GRAVEL (CFT) |

| M5 | 1 | 6.25 | 12.5 |

| M7.5 | 1 | 5 | 10 |

| M10 | 1 | 3.75 | 7.5 |

| M15 | 1 | 2.5 | 5 |

| M20 | 1 | 1.88 | 3.75 |

You can make some adjudgments to the above values based on your needs. For example, a slight increase in the quantity of sand will save the cost of cement and increase the shrinkage resistance. However, the quantities of aggregates should exceed 20% of the prescribed quantities given above. Always consult an engineer to make any changes to the quantities given above.

Litres of water needed per 50kg bag of cement

IS456 Table 9 recommends the following liters of water for M5, M7.5, M10, M15, M20 grade concrete. Typically, engineers use known quantities of containers or buckets to measure water for concrete.

| CONCRETE GRADE | LITRES OF WATER PER 50KG CEMENT BAG |

| M5 | 60 Liters |

| M7.5 | 45 Liters |

| M10 | 34 Liters |

| M15 | 32 Liters |

| M20 | 30 Liters |

Also Read:- Calculate cement sand and aggregate required 1M3 of concrete – with M20 grade concrete calculation

Leave a Reply