This article covers the Mix Design of M30 Grade Concrete as per IS10262 (CONCRETE MIX PROPORTIONING – GUIDELINES) and IS456 (PLAIN AND REINFORCED CONCRETE -CODE OF PRACTICE) Codebook.

Related Read: M30 Grade Concrete Mix Design with FlyAsh admixture and superplasticizer as per IS10262 Codebook

I. STIPULATIONS FOR PROPORTIONING

This section deals with different specifications and conditions that are expected to be fulfilled by the concrete. You can change the values in this section to meet different requirements for Mix Design of M30 grade concrete.

Please view on Landscape mode for a better view on a mobile phone.

| A | Grade Designation | M30 | |

| B | Type of Cement | OPC 53 | As per requirement |

| C | Maximum Nominal Size of Aggregate | 20mm | |

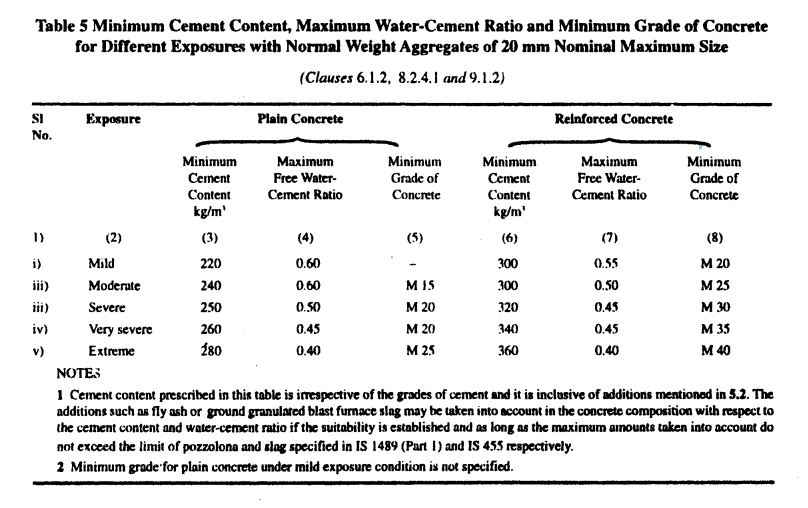

| D | Minimum Cement Content | 320kg | Table 5-IS456 |

| E | Maximum Cement Content | 450kg | As per clause 8.2.4.2 |

| F | Maximum W/C ratio | 0.45 | Table 5-IS456 |

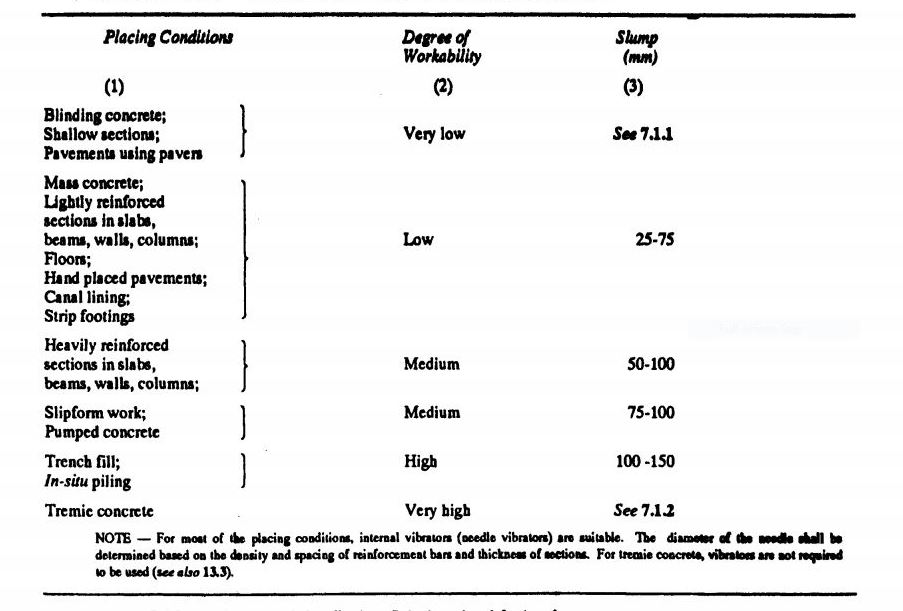

| G | Workability | 75mm | For RCC As per code |

II. TEST DATA FOR MATERIALS

Cement, sand and aggregate must be tested in a laboratory to determine their various physical properties. The standard values given here are the different physical properties of the building materials commonly used in India.

| A | Cement Used | OPC 53 | Confirming to IS8112 |

| B | Specific Gravity of Cement | 3.15 | Test – IS: 2720 |

| C | Specific Gravity of | Test – IS 2386 | |

| Coarse Aggregate | 2.74 | ||

| Fine Aggregate | 2.74 | ||

| D | Water Absorption | Test – IS 2386 | |

| Coarse aggregate | 0.5 % | ||

| Fine aggregate | 1 % | ||

| E | Sieve Analysis | Test – IS 2386 | |

| Coarse aggregate | Confirming to Table 2-IS383 | ||

| Fine aggregate | Zone II | Confirming to Table 4-IS383 |

III. TARGET STRENGTH

Apart from mix design, the strength of the concrete is influenced by other factors like mixing method, climate, curing etc. Therefore the Target strength (Fck) of the concrete should be greater than the designed characteristic strength (fck).

Target strength for m20 grade concrete can be found from the formula given in the codebook.

Fck = = fck.+1.65s

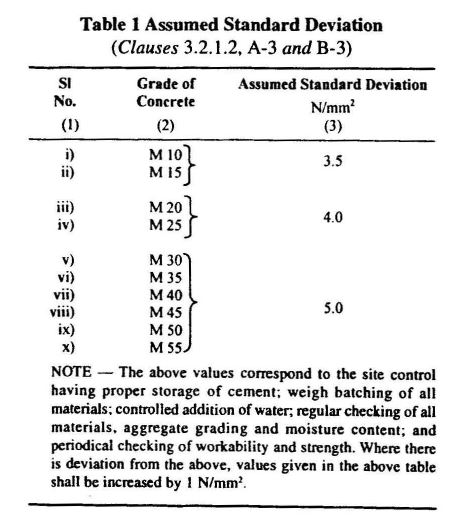

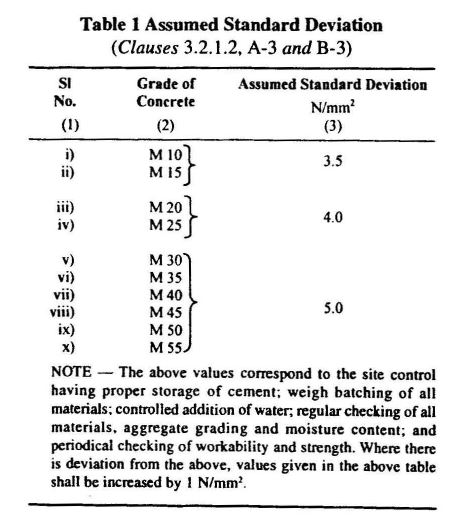

The Standard deviation (S) value for M30 grade concrete is given in table 8 of IS456.

After curing in water for 28 days, the concrete should have compressive strength greater than 38.25 N/mm2 when tested in a Direct Compressive Testing Machine (CTM).

IV. SELECTION OF WATER-CEMENT RATIO

The maximum water-cement ratio required for M30 grade concrete can be found in Table 5-IS456 given above.

| Maximum W/C ratio | =0.45 | Table 5-IS456 |

| Adopted W/C ratio | =0.45 |

V. SELECTION OF WATER CONTENT

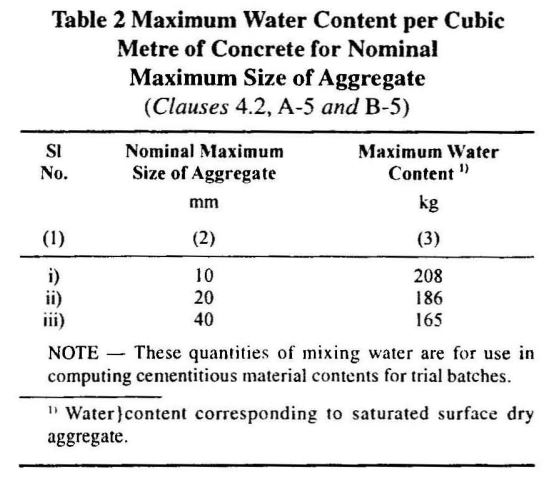

Maximum water content for 20mm aggregate to get 50mm slump is given in Table 2 of IS10262.

From above table, For aggregate = 20mm and Slump = 50mm..

| Maximum Water Content (50mm Slump) | = 186 L |

186 l of water is required to get a slump of 50mm but we need slump of 75mm as per our specifications. Clause 4.2 recommends increasing the water content by 3% to obtain an additional slope of 25 mm from the 50 mm slope

Therefore as per clause 4.2 For aggregate = 20mm, Slump = 75mm

| Water-content for 75mm Slump | = 186+(0.03*186) | As per Clause 4.2 |

| = 191.58 L | ||

| Adopted Water Content | = 190 L |

VI. CALCULATION OF CEMENT

The weight of cement for the mix design of M30 grade concrete can be calculated from the water-cement ratio and the water content.

| Adopted Water Cement Ratio | = 0.45 |

| Cement required | = Water Content / W-C Ratio |

| = 190/0.45 | |

| = 422.22 kg | |

| Adopted Cement Content | = 422 kg |

VII COARSE AND FINE AGGREGATE

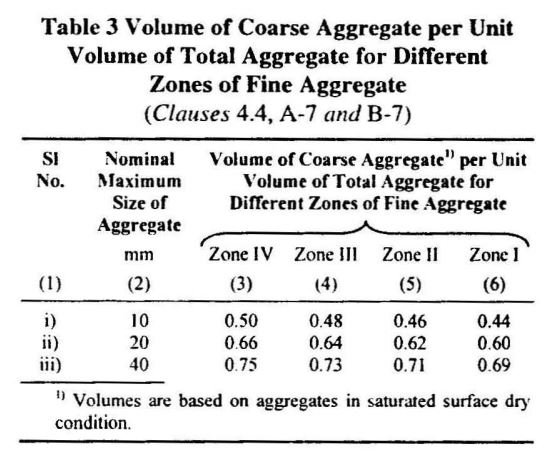

Coarse aggregate ratios for different Zones of Fine aggregates are given in Table 3 of IS10262.

From above table, For aggregate = 20mm, Fine aggregate= Zone II and Water-cement ratio = 0.50

| Coarse Aggregate ratio (For W/C =0.5) | =0.62 | Table3-IS10262 |

But we need C.A ratio for 0.45 water-cement ratio. In such cases, a value of 0.01 should be added to the C.A ratio for every 0.05 point decrease in the water-cement ratio from 0.50. So since our water cement ratio is 0.45 we need to add the value 0.01 to our C.A ratio

Therefore For aggregate = 20mm, Fine aggregate= Zone II and Water-cement ratio = 0.45

| Coarse Aggregate ratio (For W/C =0.5) | =0.62 | Table3-IS10262 |

| Coarse Aggregate ratio (For W/C =0.45) | =0.63 | (0.62+0.01 = 0.63) |

| Final Fine Aggregate ratio | = 0.37 | (1-0.63) = 0.37 |

VIII MIX CALCULATIONS OF M30 GRADE CONCRETE

This section deals with the calculation of the weight of fine aggregate and coarse aggregate from the aggregate ratio, cement and water.

| A | Volume of Concrete | = 1 cu.m |

| B | Total Volume of Cement | = Cement/(S.G*1000) |

| = 422/(3.15*1000) | ||

| = 0.134 cu.m | ||

| C | Volume of Water | = Water /(S.G*1000) |

| = 190/(1*1000) | ||

| = 0.190 cu.m | ||

| D | Total Aggregates requirement | = A – (B+C+D+E) |

| = 1 -(0.133+0.190) | ||

| = 0.677 cu.m | ||

| E | Coarse Aggregate (C.A) | = F * C.A ratio * S.G * 1000 |

| = 0.677*0.63*2.74 *1000 | ||

| = 1168.6 kg | ||

| F | Fine Aggregate (F.A) | = F * F.A ratio * S.G * 1000 |

| = 0.677*0.37*2.74 *1000 | ||

| = 686.3 kg |

Cement Fine and Coarse Aggregate needed for M30 grade concrete

| S.No. | MATERIALS | QUANTITY |

| 1 | Cement | 420 kg |

| 2 | Fine Aggregate | 685 kg |

| 3 | Coarse Aggregate (20mm) | 1170 kg |

| 4 | WATER | 190 L |

To find the design mix ratio, divide the calculated value of all materials by the weight of the cement. Therefore Mix Ratio of M30 Grade concrete by weight is Cement : F.A : C.A : Water = 1 :1.63 : 2.8 : 0.45

Related Read : Calculate Sand and Aggregated needed per 50kg bag of cement – M20, M15, M10, M7.5, M5

Leave a Reply